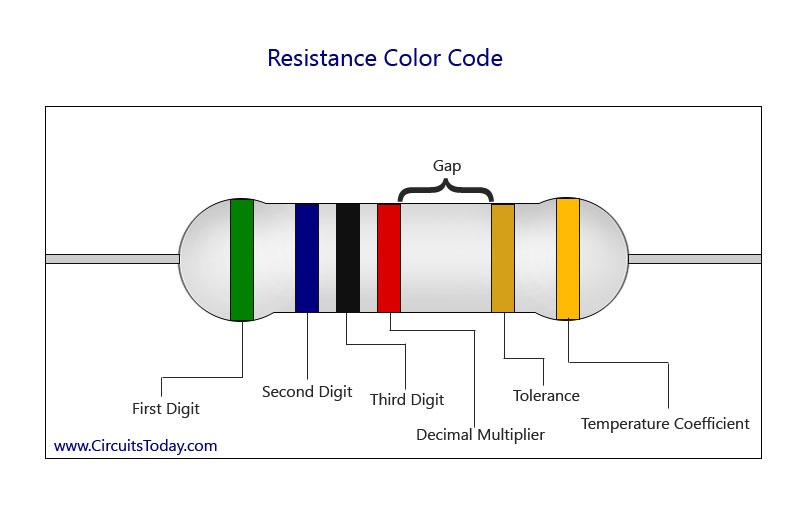

“Color coding”

is used in electronics to identify between different components. In the

case of resistors, color coding is used to identify a specific

resistance value, for example a 100 ohms resistor or a 1 kilo ohms

resistor with 5% tolerance. Electronic components like resistors are

very small in size and its difficult to print its value directly on to

the component surface. Hence a standard was formed in 1920 by then Radio

Manufacturers Association (now part of EIA – Electronic Industries

Alliance) to identify values and ratings of electronic components by

printing color codes on them. Color coding technique makes it easy to

print values (based on color codes) on small components, such as

resistors and facilitates cost effective manufacturing.

This technique of

“color coding” has 2

disadvantages. The first one appeals to general users where it becomes

difficult to distinguish between colors (for example “Red” and “Brown” )

when the component is over heated. But this is not a major concern as

the exact value can be easily identified using a multimeter (in case of

confusion). The next drawback is for a specific group of people – color

blind people can not identify the device using color codes. However they

too can depend on multimeter to identify resistance values.

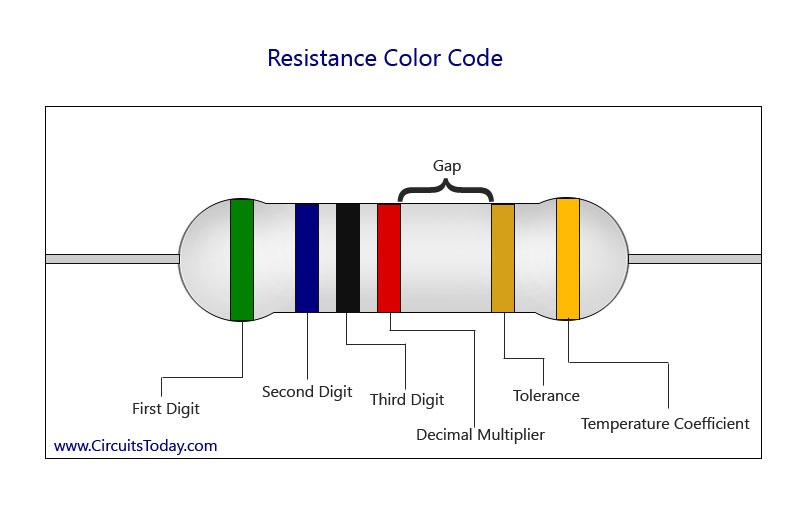

How to Identify Resistor Color Code

The figure below shows the layout of the bands, the multiplier and

the tolerance value of a resistor. For a 6-band resistor, an additional

temperature coefficient band is provided.

The gap between the multiplier and the tolerance specifies the left and right side of the resistor. So here are the key points;

4 band resistor – has 3 color bands on left side and

one color band on right side. First two bands represent significant

digits, the 3rd band represents multiplier and the fourth band on right

side represents tolerance.